Start your business with CJdropshipping

All-in-one dropshipping solution provider: product supplies, global logistics, free sourcing, POD, video shooting, and other dropshipping-related services.

CJ Blog

Liquid and power bank are special matter to transport and they need to be treated differently to avoid danger and trouble. The following will introduce the logistics of liquid and power bank.

Liquid logistics

Liquid logistics is a special category of logistics that relates to liquid products and is used extensively in the "supply chain for liquids" discipline. In other words, it is a specialized material-handling and transportation discipline that is used when moving liquid products through a supply chain.

Unlike discrete unit products, which can be moved using standard methods of transportation, liquids require specialized handling. Liquids can be shipped in a wide range of container sizes and shapes because they have no fixed dimension requirements.

Because of this, liquid logistics offers money-saving opportunities that not available when transporting solid units.

Many factors impact liquid logistics, including temperature, and the transportation methods and precautions will vary depending on the materials being moved. The available quantity of a liquid product can quickly be measured by its levels in a transport tank, and visible changes in the consistency of the liquid can be early alerts to any environmental control issues during transportation.

Sensors and flow meters may also be deployed to continuously monitor the condition of the product being transported.

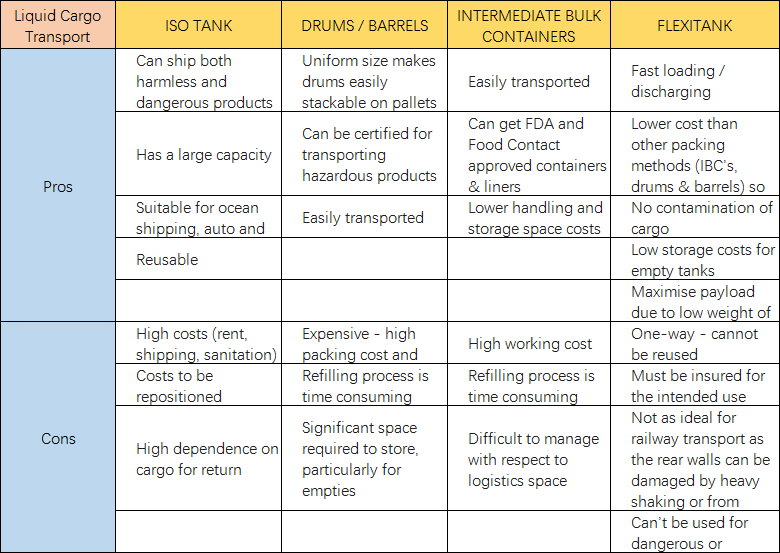

Best 4 liquid Transportation Methods

1.ISO TANK

If you transport a large capacity of liquid cargo, then ISO tanks are ideal. A 20’ ISO tank can carry 20,000 - 26,000 litres (5,300 - 6,900 gal.) of material and a 23’ container up to a huge 33,000 litres (8,700 gal.) You can also ship a wider variety of liquid cargo with an ISO tank. It is possible to ship hazardous and non-hazardous materials and in liquid, gas, or powder form.

This is because an ISO tank is built of strong steel or anti-corrosive materials for the long life and protection of your liquid cargo during transport.

However, ISO tank must be filled to 80% - 95% capacity. If the tank is under 80% full, liquids can surge dangerously in transit. Also, if it is over 95% full, it means there is insufficient room for thermal expansion - also known as the “ullage”.

2.DRUMS / BARRELS

There are many different types of drums and barrels available, such as steel, plastic and fibre. However, they are all very similar in that they require a liner or coating for food hygiene safety, and a pallet and strapping for safety.

Since drums have volumes ranging from 20 to 250 litres (5.3 - 66 gal.), they are better suited if you ship a lower capacity of liquid cargo.

It is possible to use drums to ship hazardous material, as they can be "UN Certified". On the downside, drums can be challenging to use in terms of maneuverability, safety, and storage.

3.INTERMEDIATE BULK CONTAINERS

Intermediate Bulk Containers are reusable, industrial containers made for transporting bulk liquid and granular substances such as chemicals, food ingredients, solvents, and pharmaceuticals. The size and shape of an IBC make them easy to stack and mount on a pallet, meaning they can be moved using a forklift or a pallet jack without trouble.

In terms of volume, an IBC holds around 200 to 1,250 litres, which is in between the capacity of drums and tanks - hence the term “intermediate”. With both top and side discharge/loading points, they are generally quite easy to use, without the need to transfer cargo to another storage tank.

4.FLEXITANK

Flexitanks are a special piece of equipment produced from plastic material. In essence, it is a multilayer bag with a capacity of up to 25,000 litres (6,900 gal.). These tanks are installed within a standard 20” container and the product is pumped into it, either from the top or bottom of the flexitank.

Much like the ISO tank, you must fill a flexitank up to 24 - 25 tonnes (53,000 - 55,000 lb) to keep within the maximum pressure limits allowed. Overloading can rupture the side walls of a container. However, If you underload, it cannot be insured as it is be prone to leakages. Optimising your flexitank cargo load is easy with container weighing jacks.

A key thing to remember with flexitanks is that they are only suitable for harmless (non hazardous) products. That said, they are ideal for oxygen and moisture sensitive products such as wine, flat beer and chemicals, as you can get tanks with barrier coats or osmosis prevention systems.

Power Bank

Power bank is portable power supply. Power bank cells are mainly divided into 18650 lithium battery, polymer lithium battery and AAA nickel metal hydride battery, among which 18650 lithium ion battery is the most common one in the market, with a share of up to 70%.

The European and American markets pay great attention to the safety of this kind of products. Compared with ordinary power supply, power bank has many batteries with large capacity inside, which is more dangerous than ordinary power supply battery.

Therefore, the standards of European and American countries require the internal battery to pass the relevant test and certification. In general, batteries required by the U.S. market are tested according to the standards UL 1642(cell) and UL 2054 (battery pack), while those required by the European market meet the requirements of IEC/EN 62133(battery pack and battery pack).

Intertek China has specialized laboratories in Guangzhou and Shanghai dedicated to the certification of these standards.

Shipping power bank to the US is less restricted, you can apply for booking space if you have MSDS. What's more, the packaging should be qualified, and there is no short circuit problem. It is better to control the outer packing around 10KG/ carton.

Mixed Shipping

Power bank can be mixed shipping.

In LCL, the goods are carried by two or more ships from the port of departure to the port of destination and are unpacked on the way, which is called transfer or mixed shipping.

Mixed shipping business is generally process on the remote, small, less developed port of departure or destination, because these ports have limited supply and insufficient quantity, the goods arriving at the same destination port are not easy to fill a container.

Adopt the way of mixed shipping, first the whole container is transported to a certain port of transshipment. And in the port of transshipment, a box of goods will be devanned and distributed, according to different final destination port, the goods are loaded into different boxes, and then continue to be transported to the final destination port of transport. This model can be summarized as "mixed and then direct shipping".

Obviously, mixed shipping devanns and packs one more than direct combination shipping. If transshipment port to the final destination port can’t connect, or not enough transshipment port cargo, the goods may be delay in transit port. It not only holds up time, also increases the risk of poor cargo damage. Therefore, the mixed mode is usually used when there is no better alternative.

When mixed shipping power bank, you should pay attention to:

Chat

Share